Training Offerings

We offer both online and onsite training courses designed to meet the needs of today’s manufacturing organizations. Whether your team prefers the flexibility of virtual learning or the hands‑on impact of in‑person instruction, our programs are built to strengthen skills, improve reliability, and drive measurable performance gains.

Our team stays with you throughout your journey to world‑class performance. We don’t just deliver training; we support your organization as you apply the concepts, build capability, and turn improvements into lasting results.

If you don’t see a course that fits your exact needs, we can customize a class specifically for your equipment, processes, and goals. Every organization is different, and we’re committed to delivering training that makes a real impact on your operation.

Comprehensive

Maintenance & Reliability Best Practices

Managing Manufacturing Losses

The Business of Manufacturing

Asset Management

Asset Strategy Development

CMMS Setup and Utilization

MRO and Storeroom Management

Maintenance Management

Planning and Scheduling

Operator Care

Operational Reliability

Visual Management and Centerlining

Process Development and Improvement

Defect Elimination

Root Cause Analysis

Culture and Leadership

Frontline Leadership

Assessments

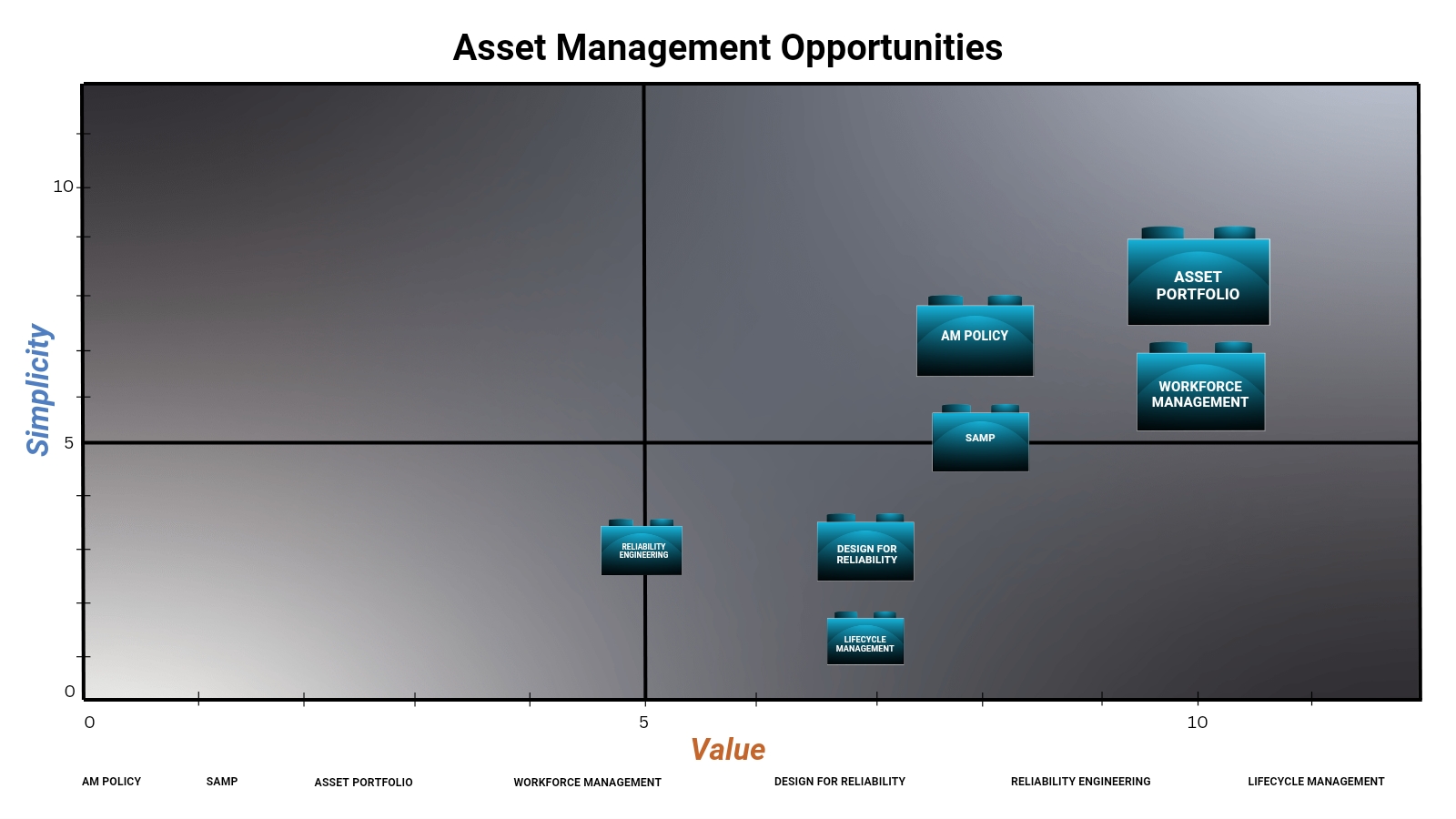

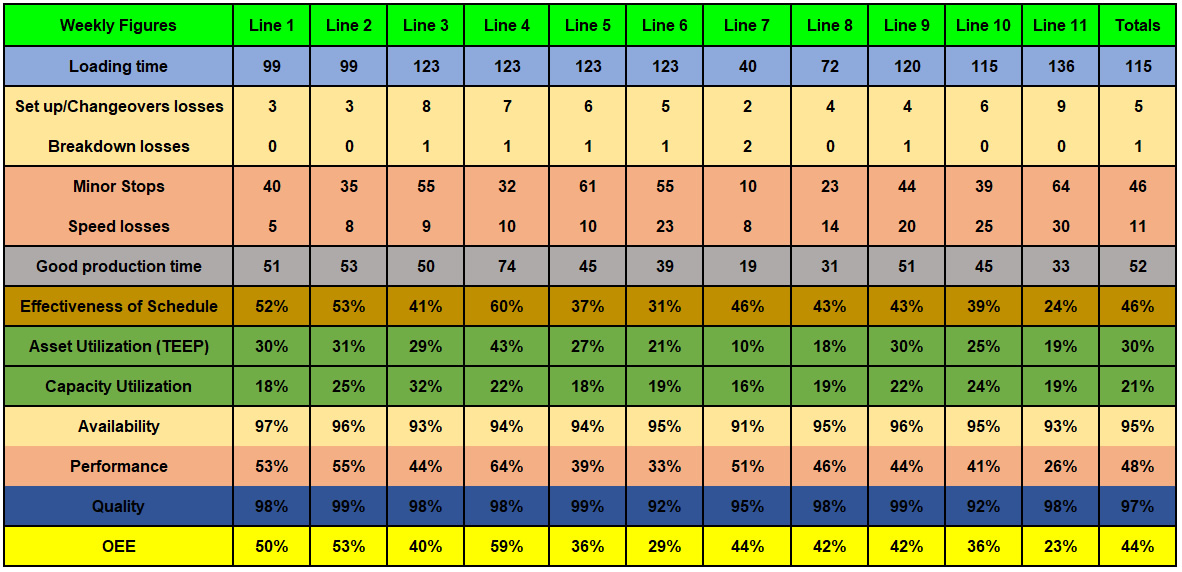

A comprehensive assessment gives you a clear, data‑driven view of the losses suppressing your OEE and the operational behaviors that allow them to persist. Built on the MRBP framework, the process evaluates how your plant manages reliability, maintenance, planning, scheduling, execution, and daily production control. Through structured touchpoints across the shop floor and within leadership routines, the assessment measures your operation against the practices that consistently drive higher OEE in manufacturing environments.

The real value comes from quantifying the impact of each loss. By connecting gaps directly to throughput, downtime, speed losses, and quality hits, the assessment shows exactly how much OEE your plant is leaving on the table. Each opportunity is prioritized by financial value, risk reduction, and ease of implementation, giving you a clear sequence of actions that deliver meaningful OEE gains quickly.

The outcome is a focused, financially grounded roadmap that helps you demonstrate early wins, build organizational support, and accelerate your plant’s path to higher OEE and more predictable performance.

See Charting Example Below:

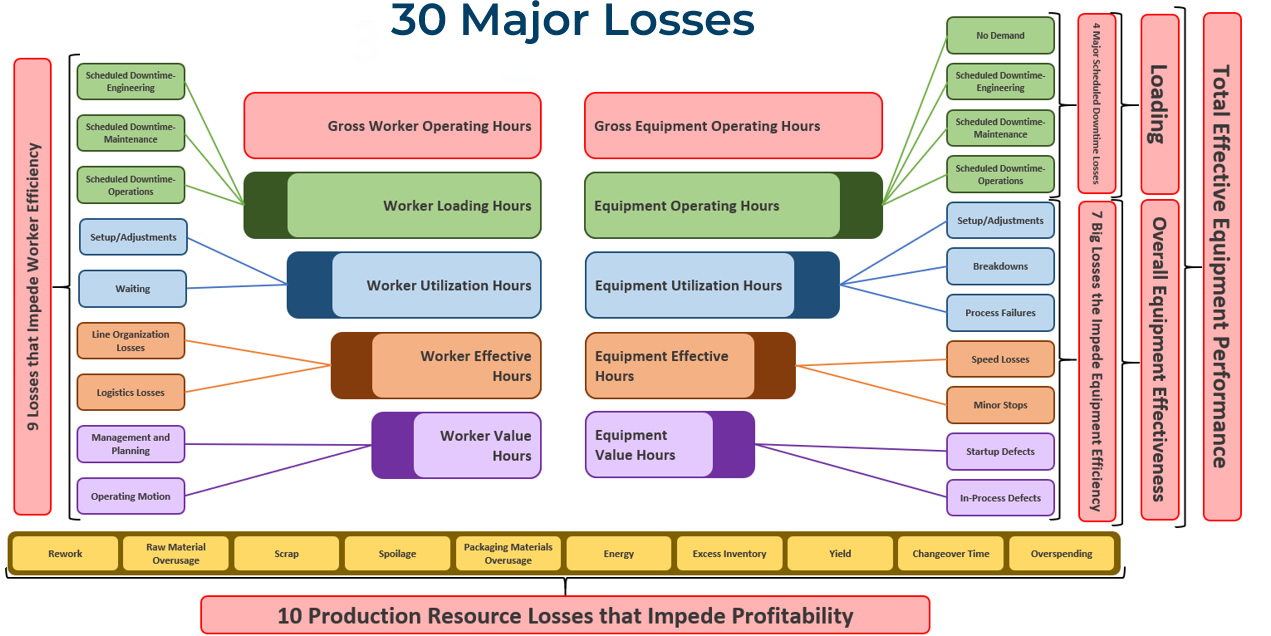

Loss Analysis

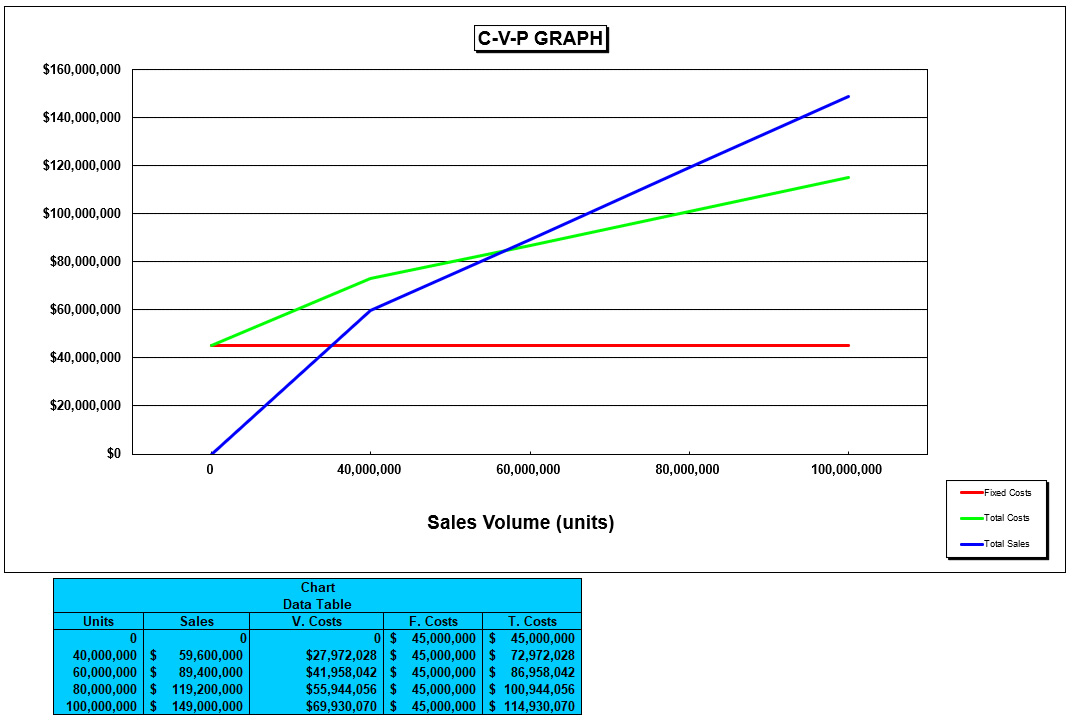

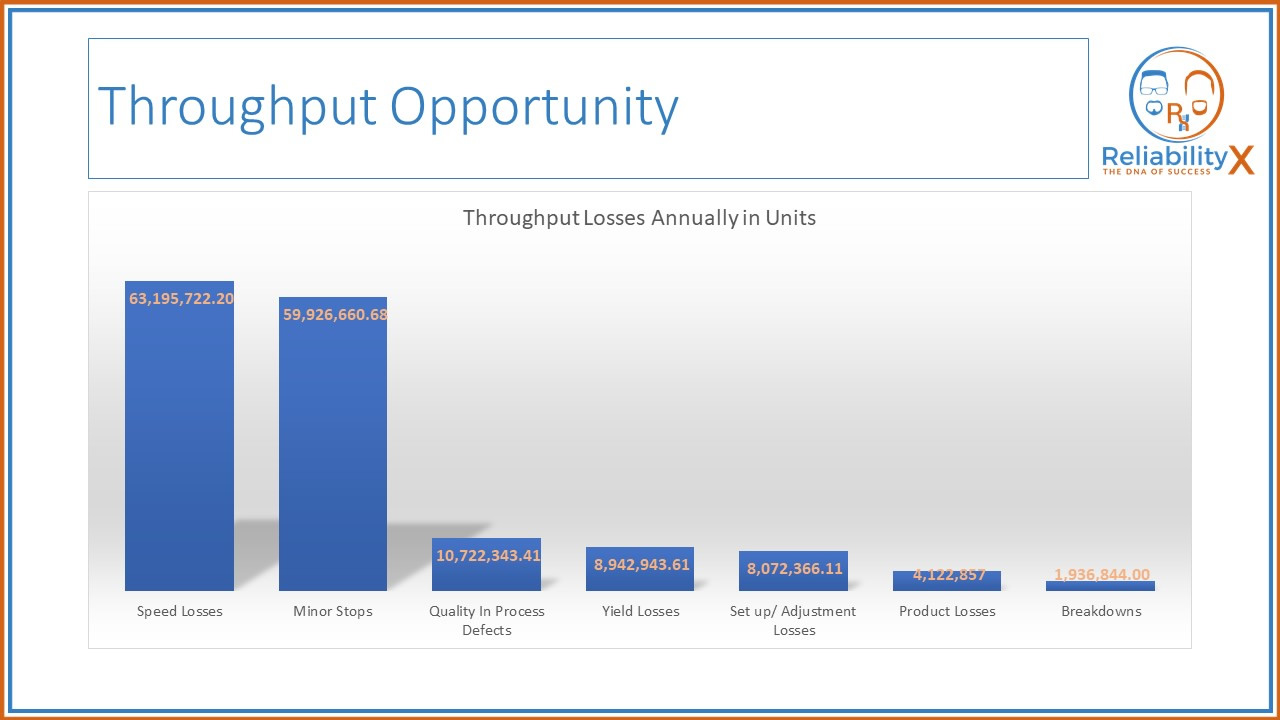

A full line loss analysis gives you a precise, data‑driven understanding of where your operation is losing capacity, why it’s happening, and how those losses are suppressing OEE and profitability. Using our 30 Major Manufacturing Loss platform, with targeted emphasis on the 7 Big Losses, we evaluate your production line at the point where value is actually created. This allows us to identify the true constraints limiting throughput and preventing the plant from performing at its designed rate.

The analysis produces a clear set of financial and operational insights, including an overall performance chart, a Cost‑Volume‑Profit analysis, a Throughput Opportunity Pareto, and a Sales Revenue Pareto. These tools quantify the dollar impact of each loss category and reveal exactly where your greatest recoverable capacity exists.

Eliminating these losses reduces operational stress, lowers costs, increases engagement, and unlocks significant throughput gains. The result is a measurable improvement in OEE and a substantial increase in profitability driven by reclaimed capacity, not additional capital.

See Charting Examples Below:

Implementation

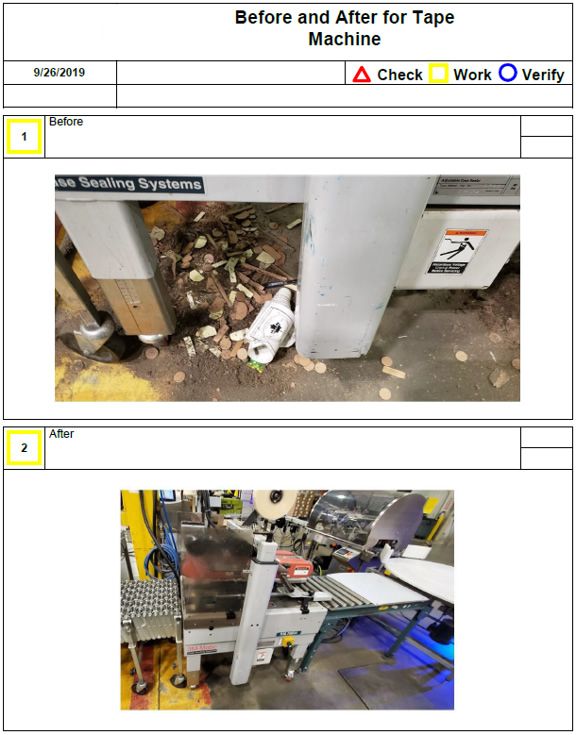

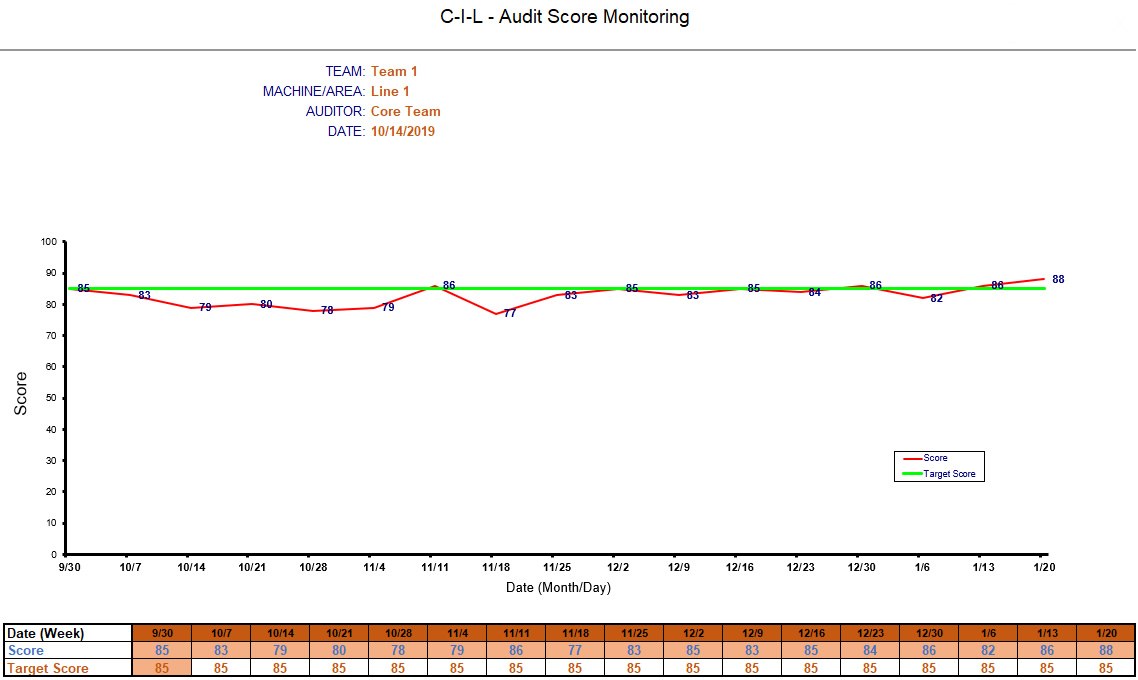

Implementation is where the transformation takes hold. Using our Holistic Manufacturing Model and the framework of Holistic Reliability, we work with your organization to align culture, daily behaviors, and operational objectives so the plant can perform at the level it was designed to achieve.

Our focus is profitability through reliability. The implementation phase targets the specific issues uncovered during the assessment and loss analysis, addressing the root causes that limit OEE, throughput, and financial performance. We work side by side with your team to eliminate these problems, strengthen daily practices, and build the capability required to solve new issues as they emerge.

Every element of the plan is designed for long‑term ownership by your organization. We train employees, establish standards, develop high‑performing teams, improve systems, and audit against the process to ensure accountability. By the time we hand off, your team is equipped not only to sustain the gains but to continue driving improvement across the operation.

This is how plants move from unstable and reactive to consistent, profitable, and high performing.

See Charting Examples Below:

Coaching and Mentoring

Coaching and mentoring at ReliabilityX are designed to build stronger leaders, elevate daily performance, and accelerate the growth of your organization. We work directly with individuals and teams to strengthen decision‑making, improve problem‑solving, and develop the behaviors that drive reliability, OEE, and long‑term operational success. Our approach blends real‑world manufacturing experience with practical guidance that helps people grow, lead, and deliver results.

Whether we are coaching leaders to execute more effectively or mentoring emerging talent to step confidently into greater responsibility, the goal is the same: develop people who can sustain improvement and elevate the performance of the entire operation.

If you want your team to think better, lead better, and perform better, this is where the transformation starts.

What is Coaching?

A coach is a facilitator of learning that passes his or her knowledge on to others. They cultivate and nurture growth within the individual, helping them to see their full potential, maximize their performance and see just how amazing they really are. Coaching focuses on the here-and-now problems while helping to set the path of excellence for others to achieve.

What is Mentoring?

A mentor is a guide sharing his or her wisdom with those less experienced. They cultivate and nurture growth within the individual, helping them to see their full potential, maximize their performance and see just how amazing they really are. Mentoring focuses on the future and a broader skill-set for future growth.